Need a Quote?

Fill out our form for a free quote

AIM is a family owned and operated company that has been proudly serving the western manufacturing sector for over 25 years. We work with innovators, entrepreneurs and corporations alike in all aspects of product design. Confidentiality is a top priority as we guide clients through the process of plastic design to prototyping to full production including packaging and distribution. We lead the way in composite and engineered resins – assisting in material selection and optimizing costs of getting products into the marketplace. We would be honored to have you join our family of over 400 clients.

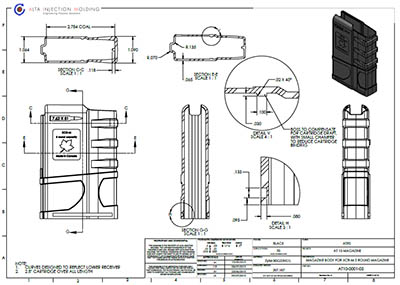

Our team of Designers work with you to transform your prototypes. During this process designs are optimized for mold manufacturing, injection molding, assembly, packaging and mass production.

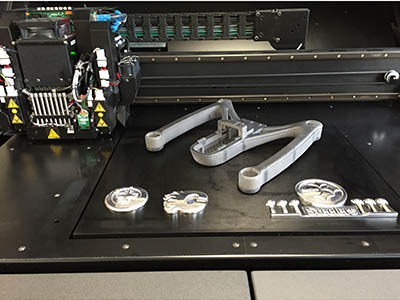

Prototyping helps to verify the design and show areas of improvement needed before the product goes into full production; prototyping is an inexpensive way to avoid costly mistakes. At Alta Injection Molding, we use a combination of 3D printing, laser cutting and CNC machining to produce functional and realistic prototypes.

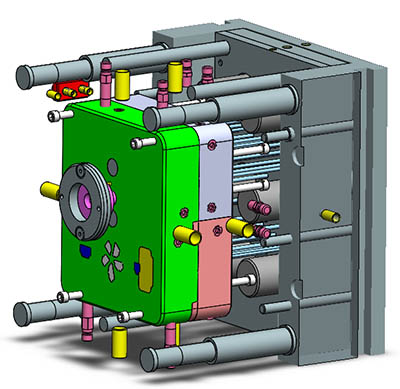

Our plastic designers and machinists work together to design cost effective molds to produce parts to our clients satisfaction.

Key areas addressed are:

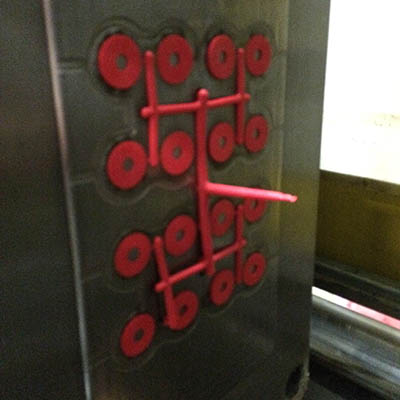

Blocks of steel or aluminum are machined via CNC mill, CNC lathe, EDM (electric discharge machining) and manual mill/lathe to the specification of the mold design. Precision and fit are key to ensure the quality of the injection molded part(s).

A mold test is done when a new mold comes into production. Process parameters are optimized to produce a fast cycle time and a quality part.

12 injection machines ranging from 70 to 800 tonnes run 24 hours a day to keep up with client demand. Our production floor is equipped for packaging and assembly of products (if necessary). Orders can range from 500 parts to millions of parts every year.

Before any product leaves the facility it must meet a quality standard provided by the client. Each product is different, and quality controls are customized in conjunction with each client.

Fill out our form for a free quote